Keithley EV Battery Testing Solutions

Keithley Electric Vehicle (EV) Battery Testing Solutions are designed for EV battery cell, module, and pack product systems that depend on precision electrical instruments to reliably identify variation. The precision electrical instruments are depended on to consistently detect tiny electrical anomalies, integrate into complex automated systems, adapt as testing requirements evolve, and deliver zero downtime.Battery Grading with OCV Testing

Battery Grading with Open Circuit Voltage Testing

Battery grading is a crucial step in any battery production environment where battery performance is key. Open circuit voltage (OCV) measurements are utilized to bin the batteries into the following grades:

• Grade A batteries feature the longest lifespans, better overall performance, and lower internal impedance, making them suitable for high-power applications like electric vehicles.

• Grade B batteries offer lesser performance and shorter lifespans and are designed for energy storage applications.

• Grade C batteries are the lowest performing and used for single-cell portable applications.

Manufacturers divide the highest quality batteries from those with internal defects, such as microshorts or contaminants. The OCV of the battery can be monitored over time to observe characterize performance and discharge trends. This process can take weeks to observe OCV changes in tens to hundreds of microvolts.

The DMM7510 is ideal for OCV testing in the production environment due to its 7.5-digit measurement resolution and superior accuracy, enabling the measuring of smaller changes in voltage and receiving results sooner. For higher volume applications, the 3706A system switch and multimeter allows up to 576 two-wire channels in one mainframe, expanding testing capabilities without losing test rack or bench space.

Battery Tab & Busbar Weld Check

Battery Tab and Busbar Weld Checking with Resistance Measurements

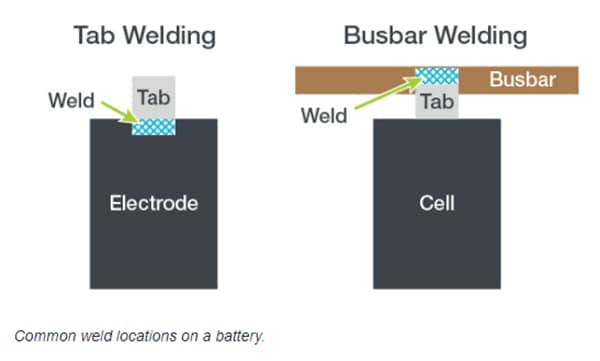

Welding is common in automated production systems to connect the cell tabs to the electrodes and to connect completed cells to form a battery pack. Large battery packs can feature tens to hundreds of welds, or joints, connecting cells to busbars.

High-quality weld joints contribute little resistance to the circuit, typically only microohms. Bad welds or joints can measure in the milliohm range, leading to performance issues and excess heat generation, potentially causing a severe thermal runaway event. It is almost impossible to visually identify a bad weld.

However, weld imperfections can be identified quickly in a production environment with a resistance measurement using a precision DMM such as the 3706A system switch and multimeter. The 3706A multimeter features high-density built-in switching, enabling more weld checks with less rewiring.

Environmental & Safety Testing

Environmental and Safety Testing using Temperature Datalogging

Environmental testing is critical to ensure batteries can withstand and perform under extreme environmental conditions. Additionally, thermal testing is an equally important part of safety qualifications. Although temperature testing varies depending on the test sequence, battery type, and physical constraints, common temperature measurements include:

• Internal temperature of a module or cell using an embedded sensor

• External temperature of a module or cell

• Monitoring the ambient temperature around the pack to verify the environmental conditions or understand heat dissipation

Because battery performance is temperature-dependent, engineers document, measure, characterize, and program the batteries into the EV when installed. Temperature is also an indicator of thermal runaway and cell failure.

Quantifying Battery Self-Discharge

Quantifying Battery Self-Discharge with Open Circuit Voltage Testing (OCV)

Batteries discharge over time when they are not connected, as the chemical slowly reverses itself internally. Ideally, this internal self-discharging current is small, so the battery can hold a charge longer. Batteries with internal defects, such as microshorts, pinholes in the separator and containments, discharge quicker over time than their higher-quality counterparts.

Faster discharge could cause poor performance and balancing issues in a pack or cause the cell to be stressed. The OCV of the battery can monitor the self-discharge behavior as the OCV decreases when the battery discharges. Dividing the good batteries from the defective ones before they are placed in a pack can require weeks of monitoring as OCV changes may only be tens to hundreds of microvolts.

The DMM7510 is an ideal solution for OCV monitoring to measure self-discharge. The 7.5-digit resolution and superior accuracy mean measuring smaller changes in voltage and viewing trends faster. For higher volume applications, the 3706A multimeter allows for up to 576 two-wire channels in one mainframe, expanding testing capabilities without sacrificing test rack or bench space.

Formation, Aging, & Battery Cycling

Formation, Aging, and Battery Cycling

A crucial part of the battery cell manufacturing process is the formation and aging stage, where vital chemistry mechanisms are established in the battery. The results of this process directly affect the battery's performance later in life, and post-formation testing is performed to identify batteries that failed to form correctly.

Formation and aging need the battery to be repeatedly charged and discharged at varying rates. Cycling the batteries is crucial in many other tests, including thermal and modeling characterization. Test procedures widely vary depending on construction, battery chemistry, and test profiles. Many other tests require the batteries to be cycled, so test solutions must be flexible.

Battery Quality

Ensuring Battery Quality with DC Internal Resistance

Batteries with high internal resistance feature lower performance and higher risk of failures like thermal runaway. Internal resistance is an indicator of a deformed solid electrolyte interphase (SEI) layer and may also be utilized as a metric for battery quality.

Check Electrode Contact Quality

Check Electrode Contact Quality with Low Resistance Measurements

Poor connection between the current collector and electrode material that is rolled onto the connector increases the battery's internal resistance. Identifying poor electrodes early on saves resources and time later in the manufacturing process.

Keep Batteries Isolated

Keep Batteries Isolated by Measuring Insulation Resistance

Shorted batteries result in the risk of dangerous failures. Shorts can occur internally, but there is also a risk of external shorts when insulation fails or a battery is connected to the pack incorrectly. Prevention of a serious failure is possible by verifying the isolation of the cell electrodes from ground and the insulation of quality materials exposed to current.